De-sizing Process

A process carried out to remove the sizing material

(like starch) from the cloth.

Objective of De-sizing

1. To eliminate the water repellent nature of sized

cloth.

2. To increase the absorbency.

3.

To reduce the

consumption of chemicals in subsequent process.

Importance of De-sizing

The

importance of de-sizing is mainly because of water repellent nature of “Sizing

materials”. So, it is important to remove the size material before conducting

any coloration or finishing process.

Enzymatic desizing

What are enzymes?

Name

·

Greek, meaning “In Yeast”

Nature

·

Bio-catalyst (proteins)

Structure

·

Usually large & complicated

Properties

·

Specific action

·

Thermo ability

·

Low energy of activation

·

Narrow working pH arrange

Classification

·

According to origin

·

According to action

·

According to structure

·

According to working temperature

Sources of Amylases

·

Malt

·

Bacteria

·

Pancreas

Requirements of desizing:

- Desizing materials

- Desizing methods

- Desizing machine

Desizing

processes

Desizing, irrespective of what the desizing agent is,

involves impregnation of the fabric with the desizing agent, allowing the

desizing agent to degrade or solubilise the size material, and finally to wash

out the degradation products. The major desizing processes are:

- Enzymatic

desizing of starches on cotton fabrics

- Oxidative

desizing

- Acid

desizing

- Removal of

water-soluble size

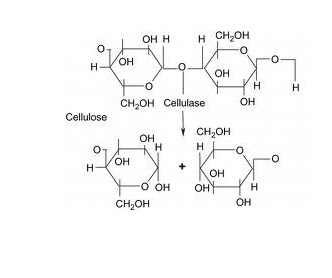

Enzymatic desizing

Enzymatic desizing is the most widely used desizing process

of degrading starch size on cotton fabrics using enzymes. Enzymes are

complex organic, soluble bio-catalysts, formed by living organisms that

catalyze chemical reaction in biological processes. Enzymes are quite specific

in their action on a particular substance. A small quantity of enzyme is able

to decompose a large quantity of the substance it acts upon..

Amylases

is the enzyme that hydrolyses and reduce the molecular weight of amylose

and amylopectin

molecules in starch, making it water soluble enough to be washed off the

fabric.

Effect of PH and Temperature

on enzyme desizing

Effective enzymatic desizing require strict control of pH, temperature,

water

hardness and electrolyte addition Activity of enzymes increase with temperature; however, above a critical temperature, enzymes are deactivated. The

effectiveness of enzymes exhibit a maximum at certain temperatures, usually 40 -75 0C. Bacterial

enzymes are the most thermally stable and can be used up to 100 0C under special

stabilizing conditions. Certain salts increase the activity of specific

enzymes. Pancreatic amylase is ineffective without the addition of salt. A

combination of sodium chloride

Exhaust Process

Enzyme 4 g/l

NaCl 4 g/l

Wetting Agent 1 g/l

Continuous Process

1. Saturate fabric with a solution containing:

Bacterial Amylase 0.8 - 1.0 %

Wetting agent 0.1 - 0.2 %

Sodium Chloride 10 %

2. Hold:

Open-width Range: Steam 1 to 2 minutes at 200 to 212 0F.

Rope Range: Store in J Box for 20 to 30 minutes at 170 to

180 0F. or

over night at room temperature.

3. Thoroughly rinse with hot water, 175 0F or hotter.

Oxidative desizing

In oxidative desizing, the risk of damage to the cellulose

fiber is very high, and its use for desizing is very rare. Oxidative desizing

uses potassium or sodium persulfate or sodium bromite as an oxidizing

agent.

Acid

desizing

Cold solutions of dilute

sulphuric

or

hydrochloric acids are used to hydrolyze the

starch, however, this has the disadvantage of damaging cellulose fiber in

cotton fabrics.

Removal of water-soluble

sizes

Fabrics containing water soluble sizes can be desized by

washing using hot water, perhaps containing wetting agents (surfactants) and a

mild alkali. The water replaces the size on the outer surface of the fiber, and

absorbs within the fiber to remove any fabric residue.

Assessment of size removal:

A drop of iodine solution placed

on a test specimen resulting in a characteristic blue color is the universal

test for identifying starch. It can be used as a qualitatively test to show

whether all the starch was removed. Absence of the blue color signifiesthat all

the starch has been removed. The intensity of the color is some what related to

how much is left. Usually, if the color is faintly perceptible, the remaining

starch will come out in the scouring and bleaching steps that follow.